Below are some pictures of our work-in-progress

242 EAST 72ND STREET NEW YORK, NY

Below are some pictures of our work-in-progress

350 ST ANN'S AVENUE BRONX, NY

We have already started our new project which consists of following work :

Facade Restoration

Parapet Replacement

Pointing and waterproofing

Lintel Replacement

140 VAN CORTLANDT AVENUE WEST BRONX, NY

We have started our new project which consists of following work :

Facade Restoration

Parapet Replacement

Pointing and waterproofing

Lintel Replacement

115 CHRISTIOPHER STREET NEW YORK, NY

We have started our new project which consists of following work :

Facade Restoration

Parapet Replacement

Pointing & Waterproofing

Lintel Replacement

Below are some pictures :

140 WEST 79TH STREET NEW YORK, NY

We have started our new project which consists of following work :

Facade Restoration

Parapet Replacement

Pointing & Waterproofing

Lintel Replacement

Below are some pictures of our work-in-progress.

1444 THIRD AVENUE, NEW YORK, NY

We have started our new project which consists of following work :

Facade Restoration

Parapet Replacement

Pointing and Waterproofing

Lintel Replacement

Below are some pictures :

200 WEST 81ST STREET NEW YORK, NY

We have started our new project which consists of following work :

Facade Restoration

Parapet Replacement

Pointing and waterproofing

Lintel Replacement

Below are some pictures of our work-in-progress

86 WEST 12TH STREET NEW YORK, NY 10011

Below are some pictures of our work-in-progress

34-43 82ND STREET, JACKSON HEIGHTS, NY 11372

We have started our new project which consists of following works:

Parapet Replacement

Stucco Replacement

Lintel Replacement

Brick & Sill Replacement

Below are some pictures of our work-in-progress

182 BENNETT AVENUE NEW YORK NY 10040

Below are some pictures of our work-in-progress

101 WEST 55TH STREET NEW YORK, NY 10019

Below are some pictures of our work-in-progress

1 UNIVERSITY PLACE NEW YORK, NY 10003

Below are some pictures of our work-in-progress

101 WEST 55TH STREET NEW YORK, NY 10019

Below are some pictures of our work-in-progress

15 ABINGDON SQUARE, NEW YORK, NY 10014

We have started our new project which consists of following works:

Local Law 11 Repair

Brick Replacement

Parapet Replacement

Lintel Replacement

Terracotta/Stucco Replacement

Pointing

Masonry & waterproofing

Below are some pictures

86 WEST 12TH STREET NEW YORK, NY 10011

We have started our new project which consists of following works:

Local Law 11 Repair

Brick Replacement

Parapet Replacement

Lintel Replacement

Terracotta/Stucco Replacement

Pointing

Masonry & waterproofing

182 BENNETT AVENUE, NEW YORK, NY 10040

We have started our new project which consists of following works:

Local Law 11 Repair

Brick Replacement

Parapet Replacement

Lintel Replacement

Terracotta/Stucco Replacement

Pointing

Masonry & waterproofing

Below are some pictures

311 EAST 72ND STREET NEW YORK, NY

We have started our new project which consists of following works:

Local Law 11 Repair

Brick Replacement

Parapet Replacement

Lintel Replacement

Terracotta/Stucco Replacement

Pointing

Masonry & waterproofing

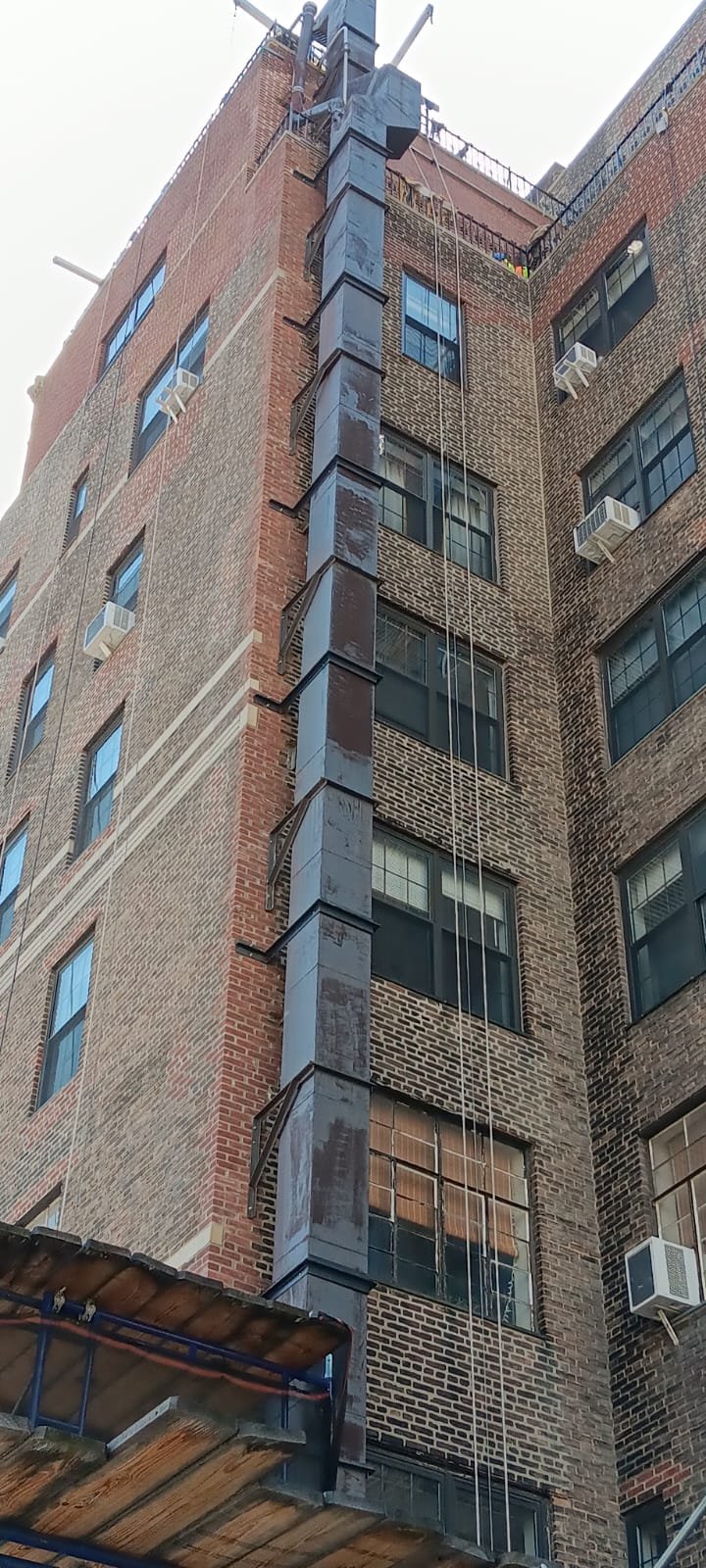

242 EAST 72ND STREET NEW YORK, NY 10012

We have started our new project which consists of following works:

Local Law 11 Repair

Brick Replacement

Parapet Replacement

Lintel Replacement

Terracotta/Stucco Replacement

Pointing

Masonry & waterproofing

Below are some pictures

166 EAST 34TH STREET NEW YORK, NY 10016

We have started our new project which consists of following works:

Local Law 11 Repair

Brick Replacement

Parapet Replacement

Lintel Replacement

Terracotta/Stucco Replacement

Pointing

Masonry & waterproofing

Make it stand out

Whatever it is, the way you tell your story online can make all the difference.